You know your operations could be better. Your team work hard, but productivity isn’t optimal — you can feel the friction. But for a risk-averse leader, especially in a highly regulated and fast-paced environment, the thought of introducing any change — never mind AI — is fraught with potentially spiralling costs. A new system, a staff restructure, an optimised process… the cost of a mistake could stall your career.

What if you could test every operational adjustment before you committed? What if you could see the future impact of a new team structure or a reconfigured supply chain, all without spending a single pound? Without disrupting business as usual?

That’s the power of predictive digital simulation modelling, and it’s how we help ambitious leaders make smarter, more confident decisions. Take 5 minutes for a snapshot of how this can work for you and your team.

Test Your “What Ifs” in a Digital Sandbox

Think of a simulation as an accurate, working replica of your business processes. We build this “digital twin” using your real-world data, creating a safe, risk-free “digital sandbox.” Here, you can run virtual experiments in minutes, not months.

This tool allows Operations and HR leaders to instantly answer critical questions:

- For Operations: What if we rearrange our production line? How do we optimise resource allocation?

- For HR: What if we add a new role to our team? How would cross-training impact our workforce’s productivity?

- For the CEO: Which process change gives us the best return on investment without disrupting our entire operation?

Testing these scenarios in a simulation eliminates common risks. You avoid costly mistakes, service interruptions, and the wasted time of a failed experiment.

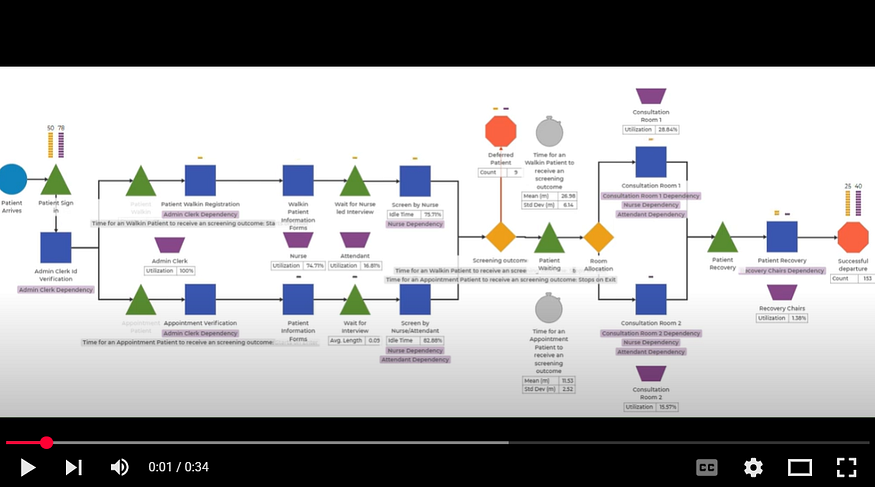

A Real-World Example | Fixing a Healthcare Bottleneck

We recently partnered with a healthcare clinic struggling with long patient wait times. There were several options for change discussed amongst the Executive Team.

Through workshopping, document and key data review, observation, integrating AI-enhanced process modelling with Lean Black Belt principles, we created a simulation of their clinic and tested the each option, with revealing results.

For example, they wanted to understand what would actually happen to their Operations if they hired another administrative clerk, which seemed like the most logical solution. The simulation showed exactly how this would impact workflow and output: follow this link to see how it displays the results of various changes, with just a few clicks.

The model showed that a new hire would only slightly reduce wait times and would quickly create a new bottleneck elsewhere. Instead, the simulation revealed a different, far more effective solution: cross-training existing attendants to assist with administrative tasks.

This simple, operational adjustment, focusing on existing resources and human potential, requires no new hires, and the model confirms that it will dramatically increase patient output and cut average wait times by over 50%.

The data has spoken — no gut feeling, no spreadsheets, no speculation. Leadership has the data-informed and AI-boosted confidence to take action. The next step is for them to do it!

Is this overkill? When does a Digital Twin become essential?

If you are an Operations Director and you know your team has been running on the same processes, systems and tools for what feels like far too long, but you cannot afford to waste time, money and effort on untested territory, then the Digital Twin is for you.

The difference isn’t just speed; it’s predictive accuracy. The integration of AI in the processes of our predictive Digital Twin modelling means thousands of scenarios can be simultaneously run in minutes. A human simply cannot do this.

Can I do this without a Digital Twin?

Of course, you don’t need all of this technology to access the answers. The simulation technologies and AI that we use at CCS are simply able to apply Lean Black Belt calculations and considerations within minutes.

What you will need in any case, though, is an experienced Lean Black Belt professional to understand your challenges, work with your team to map your process under the right lens, collect the right data, crunch that data, do the necessary calculations and present them so that your non-Lean trained staff and decision-makers understand what’s happening.

Can you afford to wait months for an answer that costs you thousands in lost productivity every day?

Ready to Stop Guessing and Start Knowing?

At Change Consulting Scotland (CCS), we believe business process optimisation shouldn’t be left to chance. We offer two clear paths to help you build a smarter, more efficient business.

- Option 1 | Done for you: Book a free initial call with us today

For leaders who need immediate results, our change management consultants will build a custom simulation for you. With over 30 years of success, our team identifies the best path forward and helps your team implement positive, lasting change. - Option 2 | Done with you: Click here to start building your own capability with CCS Lean Academy

Empower your team with these skills. Our Lean Six Sigma training is a hybrid mix of flexible online learning and live, one-on-one coaching from our experienced Lean Black Belt consultants. We give your team the tools and guidance to become masters of continuous improvement.

Stop relying on spreadsheets and guesswork. Start making operational decisions with confidence.